Introduction:

Industrial machine parts manufacturing plays a crucial role in the functioning of various industries, ranging from automotive and aerospace to electronics and construction. These parts are essential components that enable machines to operate efficiently and effectively. In this blog, we will explore the world of industrial machine parts manufacturing, discussing its significance, the processes involved, and the materials used.

Significance of Industrial Machine Parts Manufacturing:

Industrial machine parts manufacturing is vital for several reasons. Firstly, it ensures the availability of high-quality components that meet the specific requirements of different industries. These parts are designed to withstand rigorous operating conditions, including high temperatures, pressure, and mechanical stress.

Secondly, industrial machine parts manufacturing contributes to the overall productivity and efficiency of manufacturing processes. By producing reliable and durable components, it minimizes downtime and maintenance costs, allowing industries to maximize their output and profitability.

Processes Involved in Industrial Machine Parts Manufacturing:

- Design and Engineering:

The manufacturing process begins with the design and engineering phase. Skilled engineers and designers collaborate to create detailed blueprints and specifications for the required machine parts. They consider factors such as functionality, material selection, and manufacturing feasibility during this stage.

- Material Selection:

Choosing the right materials is crucial for the performance and longevity of industrial machine parts. Common materials used include metals (such as steel, aluminum, and titanium), plastics, ceramics, and composites. The selection depends on factors like strength, corrosion resistance, heat resistance, and cost-effectiveness.

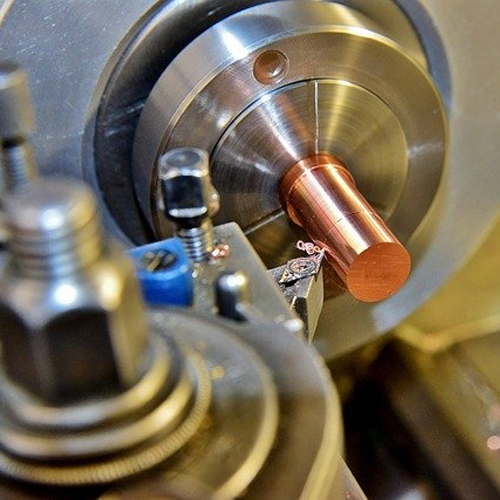

- Machining:

Machining is a fundamental process in industrial machine parts manufacturing. It involves shaping and forming raw materials into the desired shape using various techniques such as cutting, drilling, milling, turning, and grinding. Computer Numerical Control (CNC) machines are often employed for precise and automated machining operations.

- Casting and Molding:

Casting and molding processes are utilized when complex shapes large quantities of parts are required. Casting involves pouring molten metal or other materials into a mold, allowing it to solidify and take the desired shape. Molding, on the other hand, uses molds and heat to shape plastics and composites.

- Welding and Joining:

Welding and joining techniques are employed to assemble multiple components into a single part. These processes involve fusing or bonding materials together using heat, pressure, or adhesives. Welding methods include arc welding, gas welding, and laser welding, while joining techniques include riveting, bolting, and solder.

- Finishing and Surface Treatment:

After the manufacturing processes, industrial machine parts undergo finishing and surface treatment to enhance their appearance, durability, and functionality. This may involve processes like polishing, coating, plating, painting, or heat treatment, depending on the specific requirements of the parts.

Materials Used in Industrial Machine Parts Manufacturing:

As mentioned earlier, industrial machine parts can be made from various materials based on their intended applications. Some commonly used materials include:

- Metals: Steel, aluminum, titanium, and cast iron are widely used for their strength, durability, and heat resistance properties.

- Plastics: Thermoplastics and thermosetting plastics offer versatility, lightweight characteristics, and corrosion resistance.

- Ceramics: Ceramic materials are known for their high-temperature resistance, electrical insulation, and wear resistance properties.

- Composites: Composite materials, such as carbon fiber reinforced polymers, combine the advantages of different materials, offering high strength-to-weight ratios and excellent fatigue resistance.

Conclusion

Industrial machine parts manufacturing is a critical aspect of modern industries, ensuring the availability of reliable and efficient components. The processes involved, including design, material selection, machining, casting, welding, and finishing, contribute to the production of high-quality parts that meet industry standards. understanding the significance and intricacies of industrial machine parts manufacturing, industries can optimize their operations and achieve greater productivity.